The QBP

art wall, log of production phase.

The earlier stuff is Here

Finishing up January with a flurry of activity.

Permits, hoists to schedule, holes to subcontract, parts to make, copper to beat. . . . . busy busy busy .

.

a few photos.

bike being mounted to roadway frame, the guy goes onto the steel frame at the left.

The curved section that goes around the corner of the building is on the table.

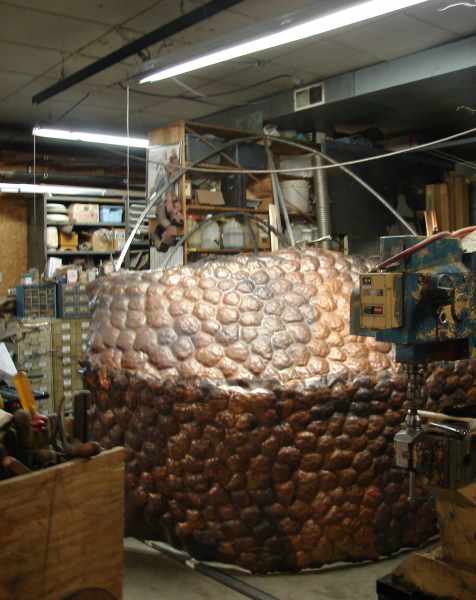

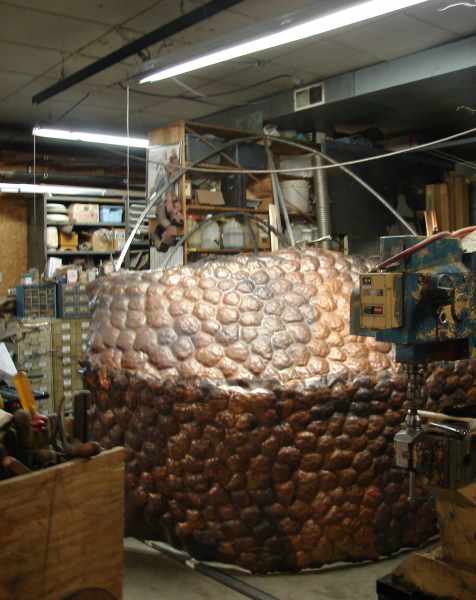

Pine tree skins

forming the texture on the deciduous trees

Week two of January

North wall road sections all framed.

Installation contractor lined up.

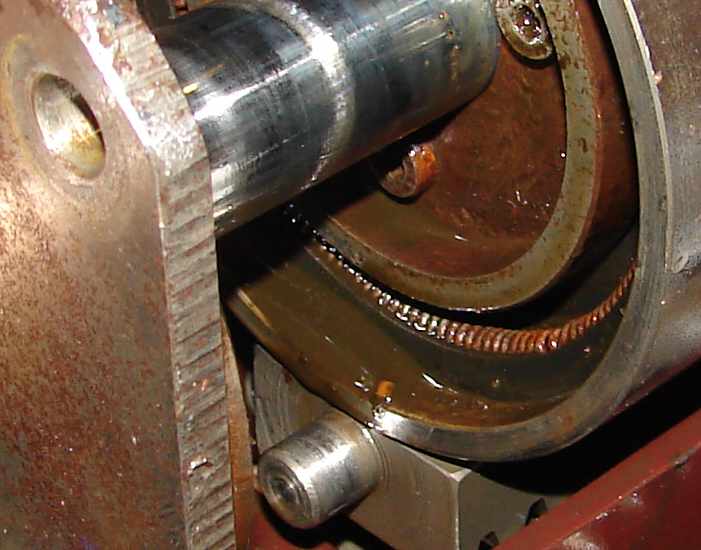

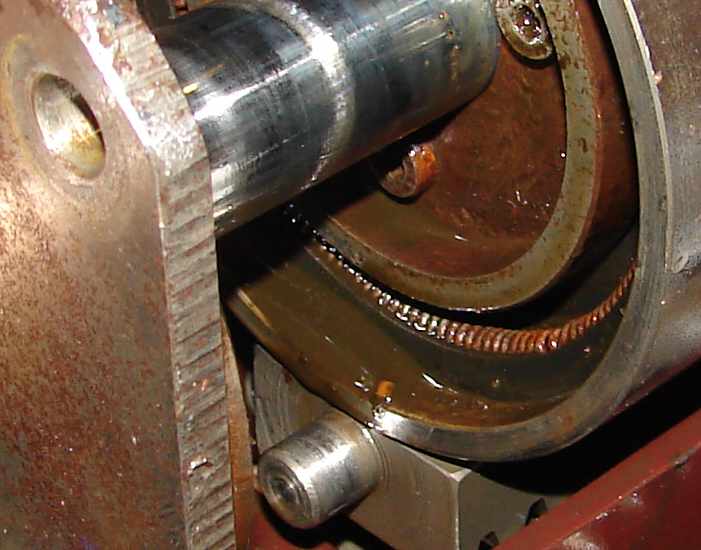

Pullmax repaired - click image to see it move

.

Last of the mounting brackets cut and ready to drill.

Copper cladding on most of North East roadway.

A start on the Bike

the bike tires.

Now we have started fabricating the bike and rider.

Bike, sprocket and chain on floor

Where are we?

Red is copper clad

Blue is stuff getting ready to be clad.

The rest of the stuff is all started, and in varying states of completion.

January ,

here already.

Originally I had planned on

building flat frames of tube and putting a copper skin over it, then

things got moved to the north wall and had to jump over roof

drains.

Then the plan was skin strength box forms on a flat frame tied to the

wall with simple mass produced mounts.

We were tossed a curve when the wall maunfacturer pointed out

that their wall was built to be there, stop the weather, but

not hold any heavy unplanned load. The strength of the wall

was in the heavy inside part, not the veneer over styro insulation

exterior. We had to transfer any tortion loads to the inner

wall, as they might crack the veneer.

We redesigned the fasteners.to match the wall.

Rich pointed out that the wall was not flat, and I noted that the north

wall venue would almost never melt and that a box structure would just

pile up with snow and stay there till spring.

unless . .

bright ideas

The swooping road as a freeform floating ribbon suspended out from the

wall on stainless trusses. With little flat surface this

would not collect snow and the individual feet could flex

enough to follow the wall's uneven surface . . . .

We have been doing a lot more work than we originally thought we would.

The result will be more dynamic and will look and work better on the

North wall.

Originally the flat panels were the jig and the mounts were finalized

after the holes were located in the buildng. (those holes would have

been drilled last week or early next and the frames would have been

coming back to us to cover).

instead each mount is unique and we have had to make huge

steel jigs to locate the holes and the mount points. (the jigs will be

around $2G in materials and we have to make them. BUT ! !

they make the difficult possible)

We are well on our way, it is just a different path.

The new path took some of us down unexpected paths.

Gene has spent a month working on complex drawings to

describe what we are doing to the city and

installer. (they like box signs, they understand them, THIS

variation, they want to see first)

the drawings are nearly done. . .

Pdf versions of

some of the drawings.

We started on the east end of the North wall and while feeding mount

point data to Cary, Gene worked on getting the drawings done ahead of

the team, Rich at getting the copper textured..

As a result the we have a spectrum of drawings the

early ones describing surface and mount points which were built off

full scale printouts of the pattern and later ones that are

more detailed and are making Cary's life easier.

The frames for the first two thirds of the road are finished,

(including the jig they sit on) . All the copper for that road section

is textured and ready to apply (1st two on*)

The buildings are all cut.out and ready to weld.

The trees are framed out,

The first two pieces of road are covered. . . (*that is ahead

of the orignial senario)

The road copper is nearly finished, the tools for texturing trees and

buildings are being played with . . .

Unfortunately, the air cyl on the pullmax died making a repair

necessary.

The old plastic rod seal disintigrated and needs to be replaced. It

will be in the shop for several days but we have plenty to

keep us busy without it.

Pieces of the broken rod seal jam under the sliding rubber

seal of the piston and let air through.

Also the old cylinder walls are badly pitted and need to be replaced.

The parts are available.

We have cut parts ready to assemble for the buildings in the city.

Cary rolls the last sections of the S curve part of the road.